- Home

- Lean expert training

- Kaizen

Kaizen

What’s

Kaizen?

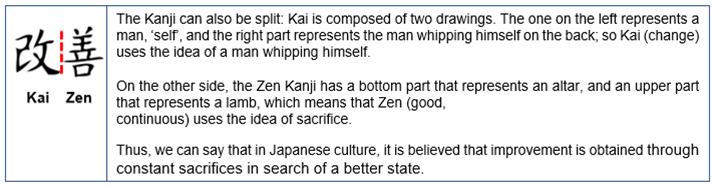

The Japanese word ‘Kaizen’ can be split in two parts: ‘Kai’, which can be translated as good, continuous, and ‘Zen’, which can mean wisdom, change, improvement. Thus, ‘Kaizen’ can be translated as ‘good change’, ‘change for good’, or ‘continuous improvement’. It is written using two Kanji or ideograms, Kai and Zen.

In many ways, Kaizen is rooted in Japanese culture. Kaizen's strategy message is that not a day should go by without some kind of improvement being made somewhere in the company.

The Kaizen philosophy is a process that aims at the continuous improvement of a business. This improvement does not mean making a significant financial investment. The philosophy of continuous improvement tries to improve the productivity of a company by making small changes every day.

Kaizen doesn´t focus only on the production process. On the contrary, it aims to suppose both a global and local improvement in every aspect of the company. Thus, with Kaizen it is intended among other things:

- Improve the quality of the product and the production process.

- Improve customer service.

- Reduce time and energy consumption.

- Reduce illness and occupational risks for workers.

- Improve working conditions, morale and motivation of workers.

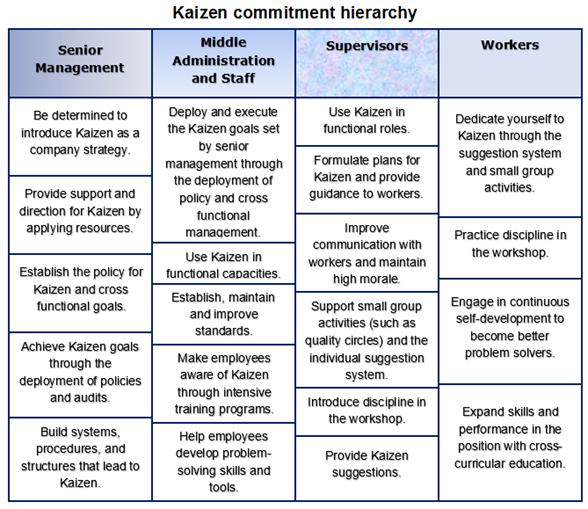

To achieve this, there are multiple elements to take into account; leadership, well-defined objectives, capacity for self-criticism, teamwork, innovative attitude, training, respect, participation or good communication, among others. One of the essential factors of Kaizen is that it not only involves the managing positions, but also involves each employee. In a given job, whatever it may be, you not only have to seek to perform tasks effectively, but you also have to try to improve at all times.

What are

the characteristics of the Kaizen philosophy?

The Kaizen philosophy seeks to implement the spirit of continuous improvement and, therefore, it will have its own characteristics:

- Its application is based on small changes, improvements or gradual and incremental innovations in the work processes that can be implemented immediately.

- Try to involve employees through suggestions in solutions. The goal is for workers to use both their brains and their hands.

- Each of us has only part of the information or experience necessary to accomplish our task. Social intelligence is of immense importance for success in a world where work is done as a team.

- Generates process-oriented thinking, as processes must be improved before improved results are obtained.

- Kaizen does not necessarily require sophisticated techniques or advanced technologies. To implement it, only simple techniques such as the seven quality control tools are needed.

- Problem solving targets the root cause and not the most visible symptoms or causes.

- Promote communication as a totally key tool for continuous improvement.

- Build quality in the product, developing and designing products that meet customer needs.

In the development and application of Kaizen, knowledge and related techniques are integrated such as:

Organizational Behavior, Finance, Operations Management, Industrial Engineering, Quality, Maintenance, Productivity, Innovation, Logistics, among others, are integrated. For this reason, under the Kaizen structure, methods and tools are involved and interrelated such as: Total Quality Control, Quality Circles, Suggestion Systems, Automation, Total Productive Maintenance, Kanban, Quality Improvement, Just in Time, Development of new products, Improvement, among others.

Advantages

of the Kaizen method:

By implementing Kaizen in an efficient way, improvements can be observed in several areas such as:

- Quality of the products or services marketed.

- Productivity (shorter production times).

- Improvement in working conditions and participation of workers (since they are committed to their work, employee-organization integration is imminent, there is a very favorable response).

Among many more improvements.

If you require more proficiency in the subject, as well as another range of materials in our international certification programs. You can find these by enrolling in the programs that InArtifexYou has for your knowledge support.

Sign up!