- Home

- Continuous Improvement Certification Online

- Lean Manufacturing Management

Lean Manufacturing Management

Lean manufacturing Management, optimize your production process

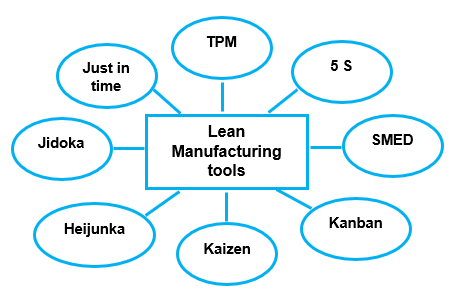

Lean Manufacturing Is not only a management tool or a methodology to produce better, is a philosophy in itself. Lean Manufacturing is a continuous and systematic process of identification and elimination of activities that do not add value in a process, but do involve cost and effort. The main philosophy on which Lean Manufacturing is based lies on the premise that "everything can be done better", in such a way that an organization must continuously search for opportunities for improvement.

This is based on a series of principles focused on removing from the environment everything that represents a waste in the production chain, understanding as waste that which does not add value to the product or to the processes. These principles are:

These

principles are:

- Generation of value: this value will be defined by the client's needs.

- Define and design the workflow that provides that value.

- That this workflow is uninterrupted, reducing downtime to a minimum.

- Implement a pull production method, that is, based on customer demand.

- Continuous improvement: excellence must be continuously sought, measuring, evaluating and executing, shaping a cycle.

As a result, an organization that applies Lean Manufacturing should adjust its production to demand, at the time and in the quantities in which it is requested, and at a minimum cost.

Thus, Lean Manufacturing can be defined as a production philosophy that groups together a set of techniques that facilitate the design of a system to produce and supply according to demand, with the minimum cost, competitive quality and high flexibility. In such a way that Lean Manufacturing will allow the organization to:

- Minimize your inventories.

- Minimize your delays.

- Minimize your workspace.

- Minimize your total costs.

- Minimize your energy consumption.

- Improve your quality.

In Lean Manufacturing, waste is any element within the production process (including service and administrative areas) that adds cost without adding value to the product, for Lean Manufacturing waste:

- It costs money $.

- It takes time to make the product and deliver it on time.

- Decreases productivity by consuming more resources.

- It increases our costs, without generating any value or benefit undermining our competitiveness in the market.

who participates Lean manufacturing?

The Lean Manufacturing methodology is executed by inclusive, organized and trained work teams. The members of the work teams involved in Lean techniques represent all levels of the organization, especially demanding the active participation of the work operators in all stages of the methodology.

Key principles and phases in the implementation of Lean Manufacturing

Organizations that seek to implement the Lean methodology or some of its tools, obviously pursue objectives related to improving the performance of their processes.

In this search, many are the organizations that have failed in obtaining significant results. For this reason, it is very important to consider that Lean Manufacturing is a philosophy that requires organizational commitment and that requires a cultural adaptation.

There are three key principles for an adequate execution of Lean activities:

InArtifexYou has certificate programs that will allow you to strategically implement the Lean Manufacturing methodology, as well as others that will make you that strategic leader in your organization.

Sign up for the materials we have designed for you!