- Home

- Continuous Improvement Certification Online

- Theory of Constraints

Theory of constraints

Theory of constraints. what is it?

Have you considered why certain elements have greater weight or relevance in an organization, financially, or also personally?

Understanding the relationship between the elements that make up a company, areas that involve a certain project, aspects of financial relevance, human factor among an alternate range that makes up a system, an organization, also attributable to a project, is possible thanks to Theory of Constraints.

The Theory of Constraints (TOC) is a comprehensive administrative philosophy, that uses the methods applied by the exact sciences to understand and manage systems based in people, organizations, among others. TOC seeks to continually generate more than the goal of a system.

The Theory of Constraints (TOC) assumes that any system, no matter how complex it may seem, is governed by very few elements, this fundamental belief of TOC is known as Inherent Simplicity.

Dr. Eliyahu Goldratt is the greatest exponent of this topic and to whom the merit of having developed a method or found a way that enables the Most of the people with the correct use of these tools a high probability of achieving better results.

Cost allocation processes, regardless of the technique used, are a wrong answer to a problem, which is not necessarily the center of discussion, the determination of the unit cost of the products. The theory of constraints (TOC) incorporates direct costs in the calculation of an indicator that will be called throughput, however, it does not require that the company try to make direct costs that are not.

The Theory of Constraints (TOC) incorporates direct costs in the calculation of an indicator that will be called throughput, however, it does not require that the company try to make direct costs that are not.

Cost allocation processes, regardless of the technique used, are a wrong answer to a problem, which is not necessarily the center of the discussion, the determination of the unit cost of the products.

Probably one of the points that has generated the most controversy around the theory of restrictions proposed by Eliyahu Goldratt is undoubtedly the one concerning the tools and techniques for measuring the financial performance of the company. For Dr. Goldratt, decision-making processes based exclusively on accounting information are totally wrong. From this basic premise, Goldratt builds what, according to him, should be the most important indicators of any company in pursuit of the primary objective of making more money.

Referred indicators:

- Throughput.

- Inventories.

- Operating costs.

Throughput: The normal definition of throughput

is total production. However, from the approach of Goldratt's theory, for the

throughput calculation, only sales should be considered and not units produced.

The reason for this situation is very simple since finished products don´t

generate income until they are sold, or better yet, until the collection of

what is sold is produced. Throughput has been defined as the speed with which

the system generates money through sales. A unit produced and not sold does not

generate throughput. Operationally, the throughput has been defined by the

following expression:

Throughput = Sale price - Cost of raw material.

Dr. Goldratt's postulates go even beyond these indicators, inscribing them in what he has wanted to call "throughput" accounting, contrasting it with the world of costs and criticizing conventional methods of identifying and determining costs.

As a starting point, this principle of making money, although simple, could be incorporated into what has been called the basic financial objective of a company, the creation of wealth for shareholders.

Additionally, financial researchers have insisted that the creation of wealth for shareholders is the result of the interaction of different elements (value levers), which are somehow reflected in net income, return on invested capital and cash flow, however it is convenient to try a relationship between the postulates of the theory of restrictions and the value of a company.

what is CONSTRAINt?

A constraint is that aspect that limits the performance of the entire system. TOC defines three main types of constraints:

- Physical restrictions: When the limitation is imposed by a machine, a material, a supplier, or in general any aspect that can be related to a tangible factor in the production process.

- Market restrictions: When the impediment to performance is imposed by conditions external to the company on the side of the demand for its products or services.

- Policy restrictions: When the company has adopted practices, procedures, incentives, or forms of operation that are contrary to its productivity or lead (sometimes subtly and inadvertently) to results that are actually contrary to those desired.

The restrictions can be internal to the company: equipment in a factory, the order preparation process in a warehouse, etc.; or they can be external, for example, the logistics of the last kilometer in an online store or the lack of demand.

Every system has at least one restriction. This is obvious, because if not your performance would be infinite. But what the theory of constraints revealed is that in practice systems usually have only one or at most a few constraints and no more.

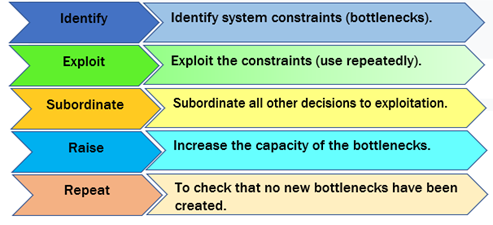

To deal with constraints in a structured way, a five-stage cyclical process is proposed, as follows:

- Identify the constraints of the system.

- Decide how to exploit the constraints of the system.

- Subordinate everything else to the previous decision.

- Elevate system restrictions.

- If a constraint is broken in the previous steps, go back to step 1.

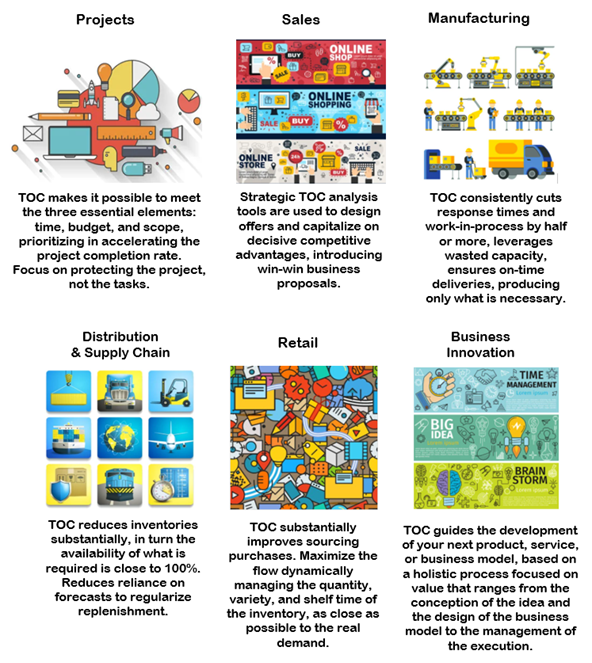

Identifying system constraints and managing them appropriately produces fast-paced results and fosters harmony throughout the entire system. From the above, we can conclude that TOC allows focusing solutions to critical problems of companies (regardless of their size or business), so that they get closer to their goal through a process of continuous improvement.

Undoubtedly, one of the most important contributions of the Theory of Constraints is that it clearly defines that it is not necessary to use 100% of the resources, since it is only desirable a maximum use of those resources with restrictions. If a resource is not considered a restriction, it should not be used more than what those with restrictions allow, since this generates problems for the company such as inventories, high levels of costs and waste in its broadest meaning.

Let us support you in delving deeper into this methodology than in complement with Lean and Six Sigma, you will achieve high impact elements for the benefit of your projects, your organization and in achieving maximum performance.

InArtifexYou certification programs will take you to new levels of comprehension about these tools.

Add up to our community!