- Home

- Continuous Improvement Certification Online

- Who Created Total Quality Management

Who Created Total Quality Management

total quality management origins?

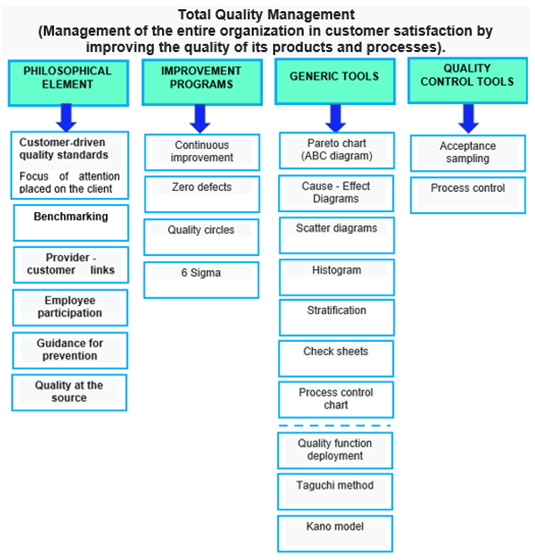

The quality approach has evolved both chronologically and conceptually from 1920 to today, going through four fundamental stages: quality control by inspection, quality assurance, total quality, and continuous improvement.

Quality has undergone a profound change to reach what we know today as Total Quality Management.

A particular actor could not be singled out as the creator or developer, since there has been a change of vision through the various actors that have given rise to what is now Total Quality Management.

Actors of the stature of Henry Ford have revolutionized since the creation of serial production, as well as an alternation of actors of great relevance in what derives from quality in our days.

The greatest focus is given to the referred "Quality Gurus", from whom their foundations and tools for current Quality Management systems such as ISO 9000 are supported, however there are other actors who have consistently supported elements in the field of quality to the extent of what we do today.

total quality management "actors"

Walter Shewart (1891- 1967).

Shewhart Cycle (PDC): Plan-Do-Check, later Deming would perfect it transforming it into PDCA. "The basic methodological process to ensure the fundamental activities of continuous improvement, maintenance, and used for a variety of approaches: Plan-Do-Check, Act", and Statistical Process Control (SPC). Shewhart's works have also contributed to the future research of several other scholars, including Deming, Jennet, Grant, and Dudding, allowing for major breakthroughs in production around the world.

W. Edward Deming (1900 -1993).

He perfected the Shewart model and gave it his own stamp by making it PDCA: Plan-Do-Check-Act, the commonly used model for continuous improvement. He also developed the fourteen points for the direction. These generated a new context for the direction of the companies (known as Deming's 14 points).

Joseph M. Juran (1904 -2008).

Juran Trilogy. - One of his greatest contributions was the development of the Juran trilogy to manage Quality, also known as the Juran Management System. "Quality planning, quality control and quality improvement are the manager's instruments in quality management." One of his main phrases "There is no control without standardization."

Kaoru Ishikawa (1915 - 1989).

Quality Circles: One of Kaoru Ishikawa's first contributions to Quality was the dissemination of the Quality Circle “Groups of volunteers, stable over time, whose main objective is to improve the quality of processes and the work environment”. Creator of one of the most used quality tools "The cause - effect diagram" also known as the Ishikawa diagram, or fishbone. One of the greatest contributions is the dissemination of the Philosophy of Quality, known as the philosophy of the Culture of Quality.

Philip B. Crosby (1926 -2001).

Zero defects. For Crosby, the absence of defects should be the performance standard for management systems and that the secret to achieving this goal is prevention. Crosby was one of the first professionals to associate Quality with pre-established requirements. Crosby handles four main maxims that he calls absolute, present in any production process that seeks to be considered effective. He generated the concept of "non-quality" pointing out that Quality is free, that the costs that are issued when Quality is not achieved are much higher than the costs generated by the General Quality System.

Armand V. Feigenbaum (1922 - 2014).

Total

Quality Control. Feigenbaum was the creator of Total Quality Control, defined

by him as an effective system to integrate the efforts of development,

maintenance and improvement of the quality of the different groups of an

organization, in order to allow products and services with lower levels than

allow full customer satisfaction. He added to Shewhart’s studies regarding

direct and indirect expenses caused by customer dissatisfaction.

Too generated the contribution of the hidden factory where he points out the non-use of methods that would avoid rework and the waste of materials drastically reduced the production potential.

This and other topics included other quality actors such as Taiichi Ohno: Just in time, Masaaki Imai: Kaizen, Genichi Taguchi: Quality Engineering, Kiyoshi Suzaki: Visual management, you will find them in the InArtifexYou training programs.